Phototypesetting: Printing’s Postwar Phenomenon

- Typesetting on film creates outlets for increased business for printers

- Results now being obtained were never visualized by manufacturers

- Printers who have invested in film typesetters enthusiastic about them

The wedding of typography or photography is a postwar phenomenon in the printing industry. During the ’30s, such a union had been discussed, but very little was done then except in the specialized area of photographic lettering.

At first it was feared the photography would eliminate hand composition and the casting of type with hot metal. The term “cold type,” claimed at about the same time as “cold war,” indicated this line of thought.

However, eight or nine years later, it is possible for us to decide what actually has happened. It is even possible to see that our “standard” procedures are not now threatened, and what’s more, probably won’t be, at least in the foreseeable future.

The other hand, this is no time to sit back and say, “I told you so.” A number of phototypesetting devices which have been developed during the past few years have been very useful, and they can easily create outlets for increased business. In experimenting with these new “gadgets,” many progressive printers have learned techniques not ordinarily at their command. It is true that in many instances the claims of inventors and manufacturers have been exaggerated. However, improvements have frequently been made by wide-awake printers after upgrading to new equipment under production conditions.

Perhaps the outstanding example of this approach is in the development of xerography by the Haloid Co., a manufacturer of photographic supplies. At first it was believed that this process would be limited to the duplication of material for libraries and other noncompetitive areas. After three years of use, it was discovered that the process could be used to produce lithographic plates. A vast new market for xerography opened immediately.

Other devices under development for type composition may have a similar history. Certainly, to use another example, the manufacturers of the Fotosetter never envisioned the many applications to which the machine has been adapted since it was introduced some seven years ago.

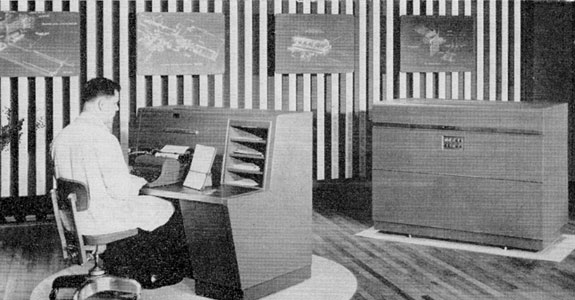

Merganthaler Linotype Company's new Hydroquadder and a pre-production model Lino-film (above) will be shown for the first time outside the United States at IPEX, the International Printing & Allied Trades Exhibition, in London July 5-16. The exhibit also will include new Davidson Dual-Lith presses.

Here is a round up, then, of new equipment which has been developed to compete with hand composition in display typography. It is problematic how many of these devices will survive and still be in use after a few years, and how many will be replaced by better machines and newer methods.

One of the first developments in the cold type field was that of letters or characters printed, black on white, on perforated cards mounted alphabetically on boards. Most well-known type faces are available, for use primarily in conjunction with typewriter composition. The operator removes the letters one at a time and positions them face down in a special composing stick. He joins the letters into a line with a strip of Scotch tape, and then removes them from the stick. Next, the word or words are pasted into position for the camera. Lines printed on the reverse side of letters facilitate proper alignment. This system is known by the trade name Fototype.

Another form of display lettering is available on acetate sheets. Artype makes a very complete line of alphabets and stock cuts, all printed on the underside of transparent sheets which are self-adhering. Each sheet contains an alphabet, printed in either black or white, with several characters of each letter or cut.

In use, the artist draws blue guide lines on his copy, which are matched by black lines printed on the sheet. The individual characters are then cut away from this sheet with a razor blade or special stylus. Next, there placed on the layout and firmly pressed down by hand. The black guide line is then removed.

Several other products are almost identical to this procedure. These are Transtik lettering alphabets, Visitype (in which the letters are printed on both sides of the acetate), Cello-Tak lettering, and Craf-Type.

Naturally enough, printers can find much to criticize when these products are handled by inexperienced operators. But when used by someone acquainted with the techniques of good type composition, they have much to offer.

This is particularly true of the many short-run jobs now produced by lithography. The printer can stock in sheet form a variety of types which would be a great deal more expensive than metal. In this way, he can offer service which might otherwise be impractical.

Invented by Lucien Bernhard, well-known type designer, Magnet Type consists of a permanently magnetic board with a black surface, on which are placed sheet steel letters which will remain in position, making possible the composition of curved or angle lines. The white on black letters are then photographed for reproduction.

The next group shows the greatest activity of all. The concept of producing display lettering by means of the camera is not recent, only in the last few years has relatively inexpensive equipment and marketed.

The Rutherford photolettering machine was a prewar device which produced lines on paper or film from alphabet plates, in a range of sizes from almost zero to 192-point. This machine was used in the production of display material for advertising, and in such specialized operations as label composition. It is no longer being manufactured.

One of the first typographic cameras to be produced after World War II was the ATF Hadego machine. Originally of Dutch design, this camera produces display composition from hand-set matrices placed in a composing stick and positioned in front of the camera lens. The mats, made of plastic, are symbols from cases of standard cap layout. The letters are white on a black background, while all spacing material is black. Two models of the machine are available, giving a total point-size range of 4-point to 115-point. The types are used are the well-known designs known to printers who use ATF types.

A more recent camera, the Fotomaster, has particular appeal to advertising typographers. This is a darkroom camera equipped with prisons with which the operator may obtain numberless effects from original copy, such as slanting forward or backward, extending, condensing, elongating, outlining, shading, reversing, etc. curved or wavy lines, circles, and other “trick those quote arrangements are possible from a single piece of copy. Strictly speaking, this camera is not a composing machine, because it photographs a line of type already set, but it is finding favor with those printers who specialize in display typography. The end product is a film or paper positive.

In the Filmotype, another display camera, a positive or reverse image on film or paper is produced from alphabet masters which the operator positions by turning the school. The character selected is then exposed by pressing the switch. Filmotype sizes range from 12-point to 144-point, in numerous type designs adapted from existing type faces.

The Coxhead-Liner is a desk-top machine which “cranks out” display composition on a 35-mm. photographic paper in a variety of type sizes, from 14-point to 72-point. The font in this camera is a disc. The operator spends it with the handle until the correct character comes into position. Then it is exposed by pressing a print key. Word and letter spacing is accomplished by dials.

The Typro photographic typesetting machine is also a desktop model, producing lines or words and sizes from 10-point to 144-point. The fonts are contained in magazines which are interchangeable, and which contained 10 to 20 different fonts. As in the other cameras, the composition is produced positive or reverse on paper or film.

No camera or darkroom is needed in Reditype to prepare a printing plate for the lithographic process. This method uses acetate letters in full fonts, a treated light-filtering surface on which to compose them, a coating material, and equipment to produce both a print and a printing plate.

The importance of all these developments should not be under-emphasized. The trade associations for several years have sponsored discussions relating to the specialized techniques of photographic composition. The International Typographic Composition Association now has a section for member organizations which own and operate photographic commitment of various kinds.

Many printers who have become actively engaged in the specialty are extremely enthusiastic about its future. They’ve spent large sums of money to buy and test the equipment into train personnel to coordinate new procedures with old, well-established skills. It is certainly to the advantage of the industry that these new methods remain part of the printing service rather than become competition which eventually will make serious inroads into the present market for composition and typography. It would seem, at this point, that adaptability to change is the most desirable attribute of today’s printer.

This article first appeared in “The Composing Room” column of the June 1955 issue of The Inland Printer.